Thermal Energy

- References

- Thermal Energy

- Project No. 1

Infrared Thermography of a Residential Villa – Detection of Thermal Losses

- Year: 2025

- Client: A. Blaser

- Municipality: Düdingen

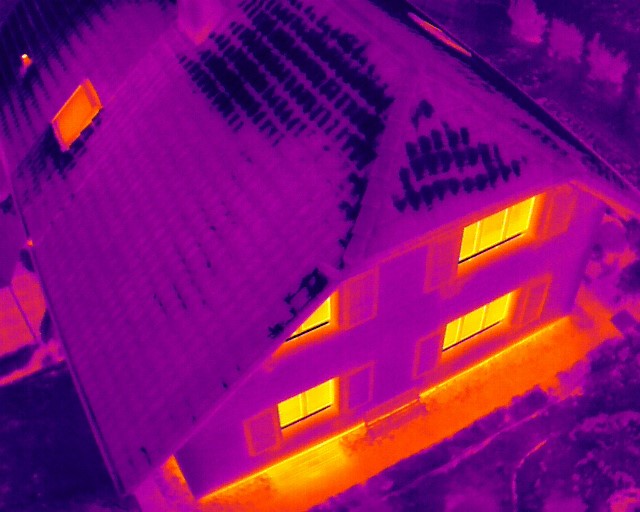

As part of a preventive energy assessment, we conducted a full infrared thermographic survey of a single-family villa. This intervention enabled the visualization of thermal bridges, heat loss areas, and potential insulation defects in the building envelope.

The analysis was carried out under controlled conditions (sufficient temperature differential, absence of direct sunlight), ensuring the reliability of the readings. The resulting thermal images were interpreted in detail to inform upcoming energy renovation work, focusing on the most effective interventions.

This non-intrusive method improves the building’s energy performance while preserving its structural integrity.

- Project No. 2

Air Tightness Testing – BlowerDoor Test in Minergie Certification Context

- Year: 2025

- Client: Moret Concept Architecture

- Municipality: Chénens

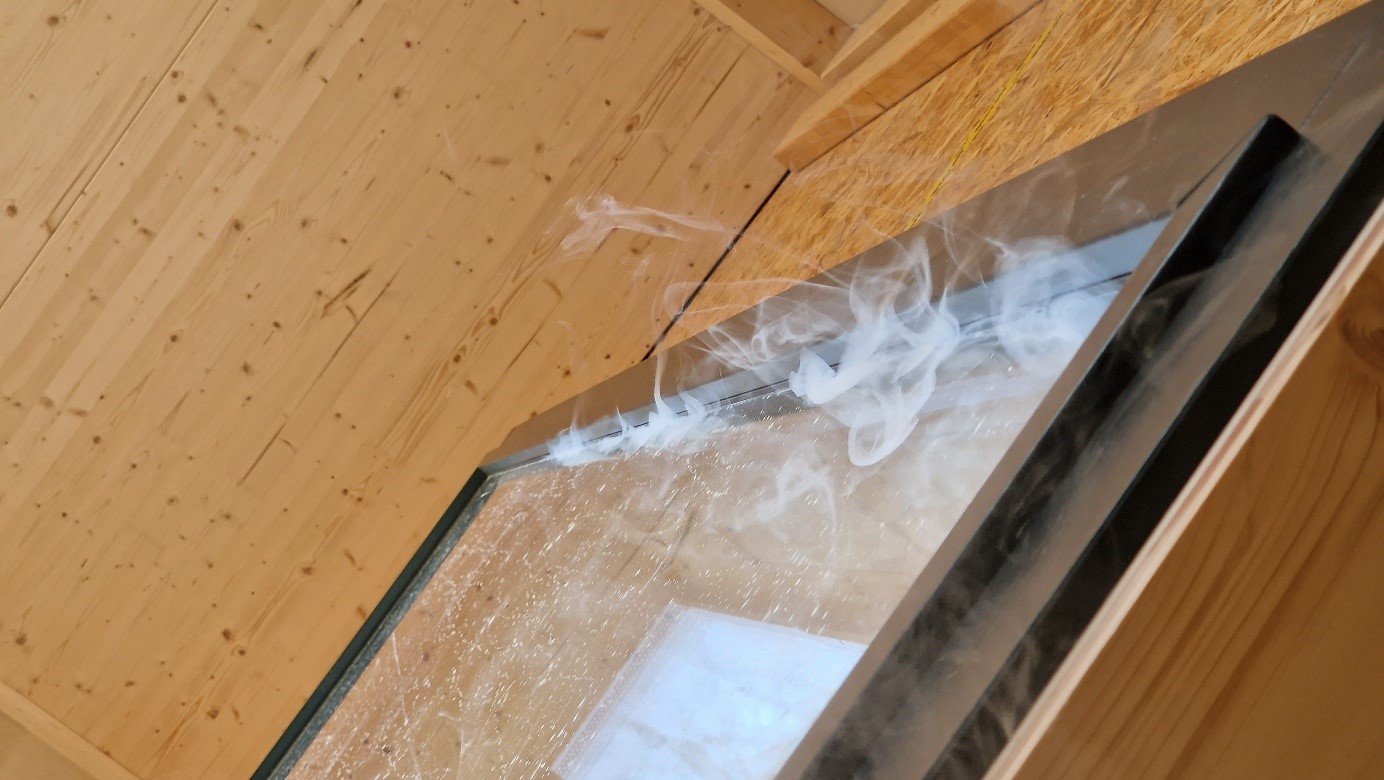

To meet the requirements of the Minergie label, we conducted a BlowerDoor test to verify the air tightness of the building envelope. This control is essential to ensure energy-efficient construction, minimize heat loss, and maintain optimal indoor comfort.

The test was performed during the final acceptance phase using a controlled pressurization system to detect unintended air leaks. The entire building was inspected using smoke pencils and thermal imaging to precisely locate weaknesses.

The results confirmed compliance with Minergie thresholds, with an n50 air change rate meeting the standard, as documented in a complete measurement report provided to the client.

This test is part of a broader commitment to high-quality and sustainable construction.

- Project No. 3

Air Tightness Testing – BlowerDoor (Minergie Certification)

- Year: 2025

- Client: Stauffacher Charpentes SA

- Municipality: Domdidier

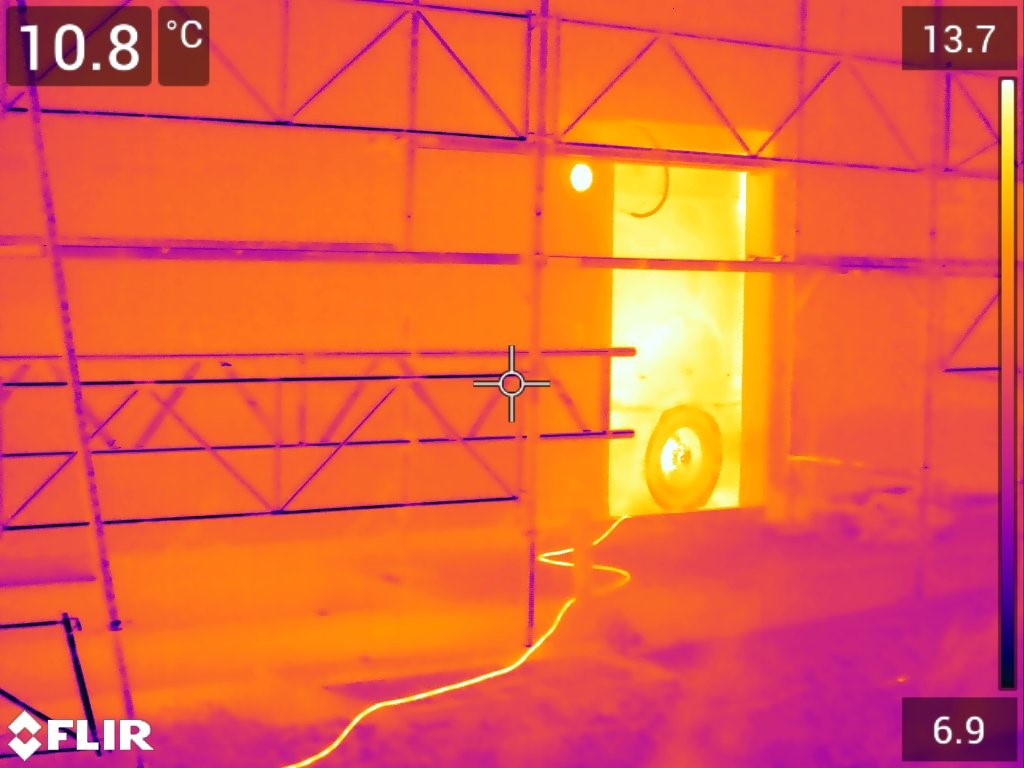

As part of a Minergie building certification, we performed a BlowerDoor test to verify the air tightness quality of the envelope. This test measures uncontrolled air infiltration, which directly affects energy performance and thermal comfort.

The test was carried out in compliance with current standards (SIA 180 / ISO 9972), using a calibrated fan mounted in an opening to create pressure differentials. This process allowed us to identify weak points in the envelope, such as leaks around windows, pipe penetrations, and material junctions.

The results were documented in a detailed report including the n50 air change value and, where necessary, improvement recommendations to ensure full compliance with Minergie standards.

This test is a key tool in validating construction quality and ensuring a high-performance, durable, and comfortable building.

- Project No. 4

Infrared Thermography of Electrical Panels – Preventive Maintenance

- Year: 2025

- Client: Michelin Recherche et Technique SA

- Municipality: Givisiez

As part of a preventive maintenance program, we performed infrared thermography on several electrical panels to detect potential abnormal overheating. This non-intrusive method allows the identification of hidden defects such as loose connections, overloads, or phase imbalances, which may lead to failures, service interruptions, or even fire risks.

Measurements were taken under normal operating conditions, ensuring a realistic and reliable evaluation. A detailed report with annotated thermal images was provided, including targeted recommendations to enhance safety and system reliability.

This proactive approach is part of a comprehensive electrical risk management strategy.

- Project No. 5

Infrared Thermography – Electrical Panels, Motors, and Mechanical Equipment

- Year: 2025

- Client: Stämpli Kommunikation

- Municipality: Bern

As part of a multi-site preventive maintenance program, we conducted an infrared thermographic campaign covering electrical panels, motors, and mechanical machines.

This intervention allowed us to detect:

- abnormal overheating on connections and circuit breakers,

- thermal imbalances on motor windings,

- and friction or misalignment in moving mechanical parts (bearings, couplings, transmissions).

Measurements were carried out under standard operating conditions to reflect actual usage. A comprehensive report was delivered, featuring thermal images and corrective recommendations, facilitating maintenance planning while reducing the risk of unplanned downtime or critical failure.

This approach fully supports a condition-based maintenance strategy, enhancing equipment reliability and lifespan.